Introduction: Powering the Future of Farming in Europe

Agriculture in Europe is undergoing a historic transformation. Over the past two decades, European farming has moved from traditional, labor-intensive methods to precision-driven, mechanized operations that prioritize efficiency, sustainability, and technological integration.

As the demand for food security, environmental stewardship, and rural revitalization intensifies, agricultural mechanization plays a central role in shaping Europe's farming future. From compact orchard tractors in Italian vineyards to high-horsepower tractors in French cereal fields, mechanization is no longer optional—it is a necessity.

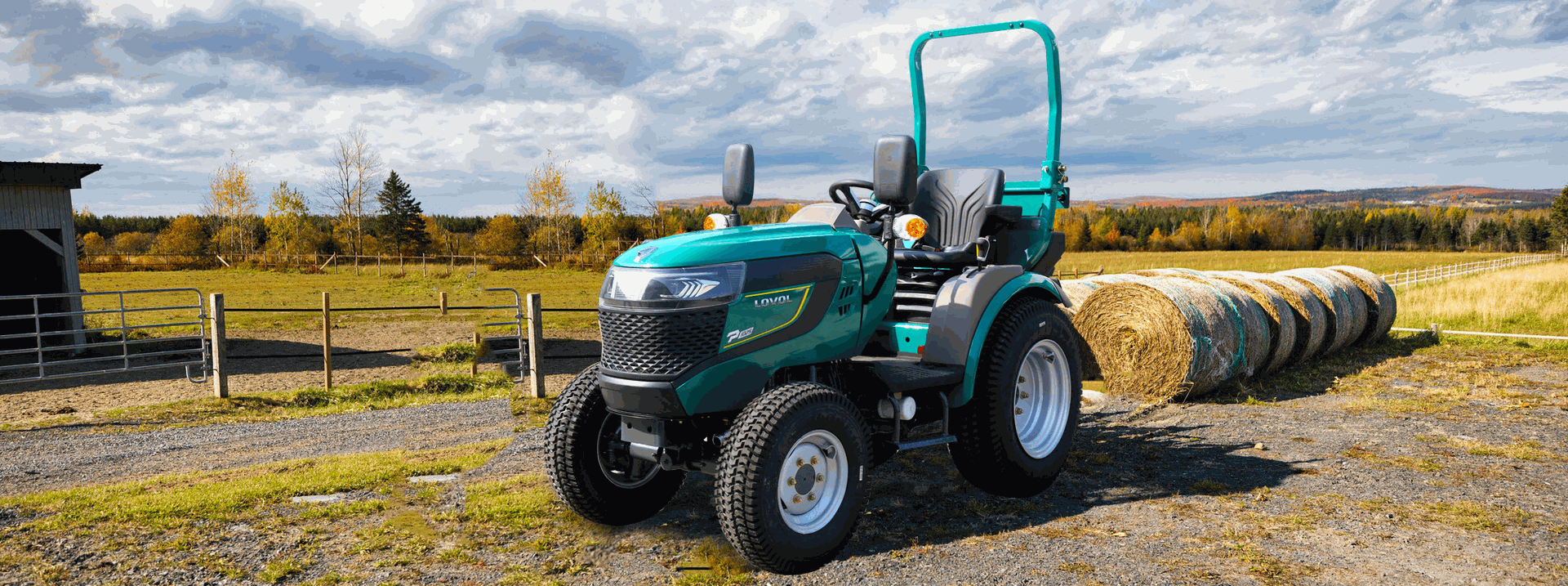

In this changing landscape, LOVOL—a globally recognized brand and China’s No.1 agricultural machinery manufacturer—emerges as a key player. With a robust product lineup designed specifically for Europe and a reputation built on reliability, innovation, and performance, LOVOL is helping reshape farming across the continent.

The Current State of Agricultural Machinery in Europe

2.1 Market Overview and Size

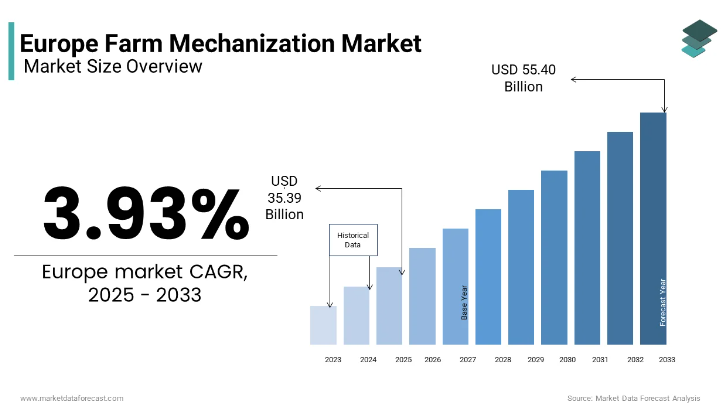

Europe represents one of the most technologically advanced agricultural machinery markets globally. According to Market Data Forecast, the European farm mechanization market was valued at USD 34.12 billion in 2024 and is projected to reach USD 55.4 billion by 2033, growing at a CAGR of 3.93%. Growth is primarily driven by:

- Labor shortages in rural areas

- The rise of precision agriculture

- Government subsidies under the Common Agricultural Policy (CAP)

- Environmental regulations that demand cleaner, more efficient machines

2.2 Equipment Trends: Shift Toward High Horsepower and Specialization

Across the continent, the market is witnessing a polarization of equipment demand:

- High-horsepower tractors (>175 HP) are gaining popularity due to their ability to handle large-scale, high-output operations, particularly in countries like France, Germany, and Poland.

- Compact and specialized tractors are increasingly used in orchards, vineyards, and mixed farms, especially in Italy, Spain, and Central Europe.

According to the European Agricultural Machinery Association (CEMA), 211,700 tractors were registered in Europe in 2023, with the high-power segment growing by 12%, while smaller machines (under 175 HP) saw a decline.

2.3 Digitalization and Precision Farming Driving Growth

One of the most disruptive forces in the European machinery market is precision agriculture, which integrates GPS, remote sensing, and data analytics to optimize planting, spraying, and harvesting.

Europe has been at the forefront of this transition, with Germany, the Netherlands, and France leading adoption. Modern farmers now demand tractors and harvesters that are not just powerful, but smart—equipped with RTK guidance, auto-steering systems, and telematics platforms.

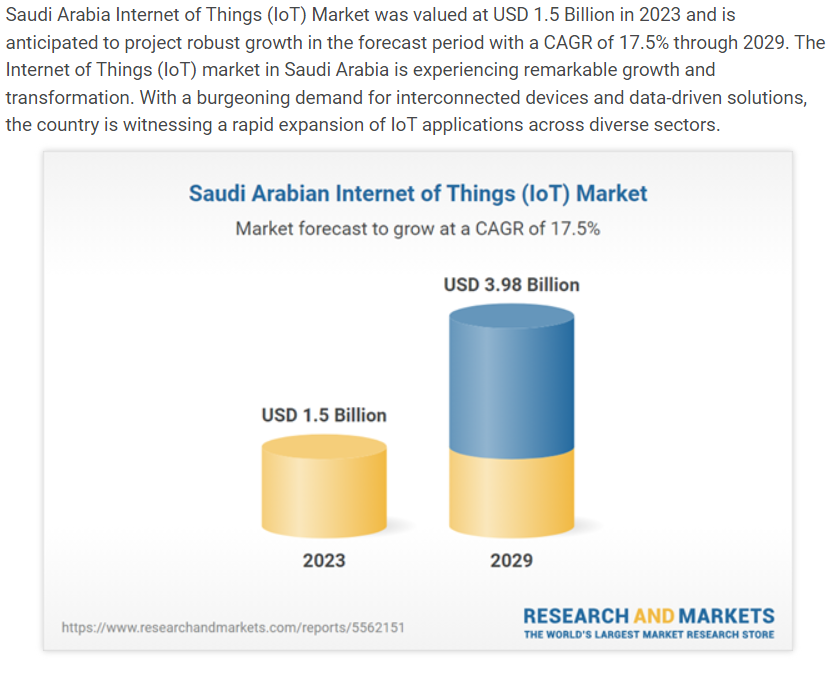

A report by Research and Markets highlights that precision farming machinery is the fastest-growing segment, with a CAGR of over 19% expected through 2033.

2.4 Key Market Challenges

Despite growth, the industry also faces several persistent challenges:

- High investment costs, particularly for small and medium-sized farms

- Complex emission regulations, such as the EU Stage V compliance, requiring costly upgrades

- Aging farmer population and rural labor shortages

- Volatile commodity prices, affecting farmer purchasing power

A study by Market Data Forecast notes that 40% of European farmers cite affordability as the top barrier to adopting new machinery, particularly in countries like Romania, Bulgaria, and Hungary.

2.5 National Highlights: Country-Level Insights

France

- Still the largest agricultural machinery market in Europe

- Tractor registrations in 2024 decreased by 7%, but average tractor power increased to 169 HP

- 300 HP machines saw a 13% growth

Germany

- Rapid expansion in digital agriculture and autonomous field machinery

- Government subsidies have encouraged investment in eco-efficient, precision machines

UK

- Despite Brexit disruptions, UK’s tractor registrations remain steady, but with a shift toward larger, more powerful models

- The average horsepower exceeded 160 HP, the highest ever recorded

Italy & Spain

- Strong demand for compact and specialized tractors for vineyards and orchards

- LOVOL’s F4000 Series is a competitive solution here, with a narrow width of 1440mm and agile operation

2.6 Socioeconomic and Political Context

Mechanization in Europe is also shaped by social and political realities:

- The EU Common Agricultural Policy (CAP) continues to subsidize sustainable mechanization, but smaller farms still face inequality in accessing high-end machines.

- According to The Guardian, the income gap between Europe’s largest and smallest farms has doubled in the past 15 years.

- Increasing environmental regulations mean that older machinery must be phased out, accelerating the replacement cycle—but adding financial burden.

The Evolution of European Agriculture: Two Decades of Transformation

Over the last 20 years, European agriculture has experienced a sweeping transformation—technologically, economically, and politically. While traditional farming practices still persist in some regions, a majority of European farms have undergone modernization, shaped by policy shifts, structural changes, and technological revolutions.

3.1 Policy Framework: How the EU Shaped Farming

TheCommon Agricultural Policy (CAP) has been the primary driver behind Europe's evolving agricultural landscape. Since the early 2000s, CAP has reoriented its focus toward:

- Moderation of rural infrastructure

- Environmental protection and sustainability

- Mechanization and productivity incentives

Between 2007 and 2023, over €350 billion was allocated to CAP programs, including rural development funds that helped farmers invest in tractors, harvesters, and precision tools.

Starting in 2023, the reformed CAP prioritizes climate-smart technologies and digital innovation a major catalyst for the adoption of advanced machinery. [From Official EU CAP Reform Portal]

3.2 Structural Changes in Farming

Farms in Europe are becoming fewer, larger, and more specialized:

- The total number of farms in the EU declined by 37% between 2005 and 2020, according to Eurostat

- Average farm size increased by 43% in the same period

- Larger farms are more likely to invest in **modern machinery and digital platforms

Smaller farms, meanwhile, are adapting through diversification (e.g., agritourism) and low-horsepower compact tractors, which offer better value and flexibility—this is where brands like LOVOL’s P1000 and M2000 series offer real competitive advantage.

3.3 Technology: From Manual to Digital

The rise of digital agriculture is arguably the biggest leap forward:

Year | Technological Milestone |

2005–2010 | Introduction of GPS-guided tractors |

2010–2015 | Growth of telemetry, sensors, ISOBUS compatibility |

2015–2020 | Expansion of RTK-based auto-steering systems |

2020–2025 | AI-powered decision support, drone integration, CVT tractors |

Today, a new tractor in Europe is likely to come with Stage V engine compliance, RTK GPS compatibility, smart implement controls, and digital dashboards. Farmers are no longer just machine operators—they are data analysts, machine managers, and business strategists.

LOVOL has aligned with this trend by offering features like LCD digital displays, ergonomic cabs, synchro shuttle transmissions, and smart compatibility with implements.

3.4 Sustainability & Green Agriculture

Climate and sustainability have become non-negotiable priorities in European agriculture:

- Stage V emission standards—all new tractors must meet stringent NOx and particulate limits

- Eco-schemes under CAP incentivize low-emission machinery and reduced fuel usage

- Organic and regenerative farming growth requires compact and soil-friendly machinery

LOVOL tractors with Doosan and Weichai engines meet Stage V standards while offering high torque at low RPM, optimizing fuel use and emissions performance.

Local Case Studies: How Mechanization Changed European Farming

Real-world success stories underscore the importance of mechanization. Below are selected case-based narratives.

4.1 Case Study – Orchard Modernization in Northern Italy

Background: Northern Italy is known for its high-value apple and wine grape production. Traditional farms here typically span 3–5 hectares, with narrow lanes and dense plantings.

Problem: Conventional tractors were too wide and lacked the maneuverability needed for such tight orchard work. Farmers also faced increasing labor shortages and CAP pressure to reduce emissions.

Solution: The LOVOL F4110 orchard tractor was introduced in 2024 to a group of cooperative vineyards. With a compact width of 1440mm, a Stage V Weichai 3.6L engine, and 16x16 synchronized transmission, farmers saw:

- 20% fuel savings

- Reduced labor dependency by 35%

- Improved soil health due to lighter chassis weight and precision implement compatibility

This tractor proved to be a game-changer for mid-sized orchards focused on sustainability and efficiency.

4.2 Case Study – Smallholder Farm Mechanization in Romania

Background: In Romania, over 50% of farms are smaller than 5 hectares. These farms often rely on manual labor and outdated equipment, limiting productivity and market competitiveness.

Problem: Small farms cannot afford high-powered machines, and EU subsidies are often difficult to access due to complex regulations.

Solution: With the introduction of LOVOL P1025 and M254 sub-compact tractors, smallholders gained access to affordable, reliable, and efficient machinery for:

- Tillage, hauling, mowing, and spraying

- Municipal tasks like snow clearing in winter

Key results from a community pilot in 2023:

- Increased yield output by 22%

- Reduced total labor hours by 41%

- Improved tractor uptime due to reliable Yanmar/Doosan engines and simple mechanical transmission

4.3 Case Study – High-Power Mechanization in France’s Wheat Belt

Background: In northern France, large-scale wheat and oilseed farms span over 200 hectares on average. Equipment reliability, fuel efficiency, and operator comfort are critical.

Problem: Existing equipment aged over 10 years suffered from frequent breakdowns and poor fuel economy.

Solution: In 2024, a regional distributor introduced the LOVOL P5130 to a cooperative group. With a 4.6L turbocharged Weichai engine, 3-speed power shift, and power shuttle, the machine delivered:

- 32% reduction in downtime

- 25% improvement in fuel efficiency

- Positive operator feedback on Grammer seat, LCD display, and panoramic cab comfort

Whether it's narrow orchard rows in Italy, diversified micro-farms in Romania, or large-scale production in France, LOVOL has demonstrated its ability to adapt to the local terrain, regulatory environment, and farmer needs.

LOVOL's Global Vision and Strategic Growth in Europe

LOVOL is more than just a machinery manufacturer—it's a global agricultural technology provider driven by engineering excellence, full-chain innovation, and customer-focused solutions. As China's No. 1 agricultural machinery brand, LOVOL has continuously expanded its global footprint, with Europe emerging as a strategic market for both innovation and growth.

5.1 A Global Brand With Local Insight

Founded in China, LOVOL has grown to become a world-class agricultural machinery manufacturer, exporting to more than 120 countries and regions worldwide. In Europe, the LOVOL name stands for precision, power, and reliability—backed by:

Compliance with Stage V EU emissions regulations

- Region-specific product development

- Growing local dealer and service networks

- Multi-language technical support and spare parts supply

LOVOL’s success is rooted in local adaptation. Our tractors, harvesters, and implements are tailored for European terrain, farm sizes, and crops—from vineyards in Spain to livestock farms in Germany.

5.2 European Market Entry: Progress and Achievements

In the past 5 years, LOVOL has rapidly expanded its European presence through:

- LOVOL Europe Website: A dedicated English-language platform for product showcases, tech support, and inquiries

- EU-Ready Product Certification: Full product line aligned with EN/ISO standards and Stage V emission norms

- Exhibition Participation: Featured in events such as Agritechnica (Germany), EIMA (Italy), and SIMA (France)

- Strategic Distributor Networks in countries like France, Italy, Romania, Poland, and Germany

- After-sales service centers and spare parts warehouses set up to reduce downtime for European users

LOVOL Tractor Series: Engineered for Every European Farm

LOVOL’s tractor offerings for Europe are split into multiple platform series, each tailored to a specific segment of farm size, task complexity, and terrain.

6.1 P1000 Series – Sub-Compact Tractors for Small Farms and Hobbyists

⭐Model: P1025 Sub-Compact Tractor 25HP | Yanmar Stage V Engine | 8F+8R Synchro Shuttle

- Ideal for landscaping, greenhouse work, hobby farming, and rural households

- Small turning radius and compact dimensions fit tight spaces

- Versatile implement compatibility (rotary tillers, mowers, snowblowers)

6.2 P2000 Series – Compact Tractors for Municipal and Orchard Work

⭐ Model: P2040 Compact Tractor 40HP | Doosan Stage V | 8F+8R Shuttle

- Optimized for orchard maintenance, vineyard tillage, urban landscaping, and light fieldwork

- Robust yet maneuverable design with reliable performance

- Supports front loaders and backhoe attachments

6.3 M2000 Series – Practical and Affordable Compact Tractors

⭐ Models 1: M254 (25HP) – Small farms, orchard rows, daily tasks

⭐ Models 2: M404 (40HP) – Mid-sized farms, field prep, loader work

- Compact yet powerful 3-cylinder Stage V engines

- Comfortable operation with 8F+8R shuttle transmission

- Ideal for smallholder modernization** and **multi-use farming

6.4 M3000 Series – Mid-Size Utility Workhorses

⭐ Models 1: M504 / M504Pro (50HP)

⭐ Models 2: M754 (75HP)

⭐ Models 2: M904 / M1004 / M1104 (90–110HP)

- Doosan Stage V engines for clean, powerful performance

- Reinforced 3-axis transmission, 12F+12R synchro shuttle

- Equipped for loader work, plowing, transport, and municipal operations

- Premium variants offer Grammer seat, LCD digital panel, mobile charging, and adjustable steering

6.5 P4000 Series – Advanced Utility Tractors for Livestock and Tillage Farms

⭐ Model: P4110 110HP | Weichai 4.6L Turbocharged Engine | Power Shuttle

- Excellent for medium-sized farms, livestock feed transport, and implement-heavy tillage tasks

- Advanced cab comfort with panoramic visibility

- Strong torque performance with low fuel consumption

6.6 P5000 Series – Premium Performance for Demanding Operations

⭐ Model: P5130 130HP | 4.6L Weichai + 3-speed Power Shift

- Designed for continuous high-load fieldwork

- 3-speed power shift allows seamless operation under varying conditions

- Power shuttle and electro-hydraulic controls for operator ease

- Premium cab: climate control, Grammer seat, digital instrument cluster

6.7 F4000 Series – Orchard Specialist Tractors

⭐ Model: F4100 110HP | Weichai Stage V | Ultra-Narrow Width: 1440mm

- Built specifically for orchards, vineyards, and berry plantations

- Compact frame allows tight turning radius without damaging tree roots

- Fully synchronized 16x16 transmission or optional power shuttle version

From 25HP sub-compacts to 130HP high-performance tractors, LOVOL offers a full power spectrum adapted to:

- Smallholders and municipal clients

- Orchard and vineyard operations

- Mixed-use and livestock farms

- Large-scale field and tillage farms

Combined with premium features, engine variety, and local compliance, LOVOL provides European customers with cost-effective and durable alternatives to traditional brands.

LOVOL Full-Solution Mechanization: Implements, Harvesters, and Smart Farming

LOVOL's strategy goes far beyond selling tractors. As a full-chain agricultural machinery provider, LOVOL delivers a complete mechanized solution—from soil preparation to harvest, covering every link of the agricultural process.

This ecosystem includes:

- ✅ Tractors (20–500HP)

- ✅ Implements (tillers, plows, seeders, sprayers, balers, etc.)

- ✅ Harvesters (tracked and wheeled)

- ✅ Precision farming components

- ✅ Service + parts + diagnostics

7.1 Implements – Powering Smart & Efficient Fieldwork

LOVOL manufactures a wide range of agricultural implements engineered for precision, durability, and seamless integration with LOVOL tractors.

Key Implement Categories:

- Tillage Tools: rotary tillers, disc harrows, cultivators

- Seeding & Planting: precision seeders, potato planters

- Crop Care: sprayers (mounted and trailed), weeding machines

- Harvest Logistics: balers, trailers, grain carts

- Post-Harvest: grain dryers, straw processing equipment

✔ Modular design allows easy coupling with both compact and high-power LOVOL tractors

✔ Stage V compatible PTO systems

✔ Implement + tractor bundles offered in select European markets

7.2 Harvesters – Engineered for Performance and Versatility

LOVOL’s harvesting line includes both wheeled and tracked harvesters designed for high performance, low crop loss, and reliable operation.

Wheeled Harvesters (175–500HP)

- Designed for large European fields

- Equipped with wide headers (2–9m)

- Features: intelligent cutting height control, auto-threshing, ISOBUS compatibility

Tracked Harvesters (88–130HP)

- Specially designed for wet fields and paddy crops

- Excels in lodged crop recovery and uneven terrain

- Compact and agile, suitable for Eastern Europe and Balkan terrains

✔ Customized header options: wheat, maize, rice, rapeseed, cotton, sugarcane

✔ Efficient separation and cleaning tech improves grain quality

✔ Smart monitoring systems reduce operator error and post-harvest losses

7.3 Golden Power Chain® – Proprietary Core Components

LOVOL is the only Chinese agricultural brand to fully control and self-develop all core powertrain technologies through its Golden Power Chain®:

- Weichai Engines – High-efficiency, low-emission powerplants

- Linde Hydraulics – German tech precision for lifting & steering

- Hande Axles – Heavy-duty axles for high load-bearing

- Fast Gearboxes – Advanced transmission systems with smooth shift logic

This integration delivers:

- Greater mechanical reliability

- Lower emissions and noise

- Simplified maintenance and spare parts logistics

Ready to power your productivity with smart, sustainable agricultural machinery?

Click on"Contact US" below